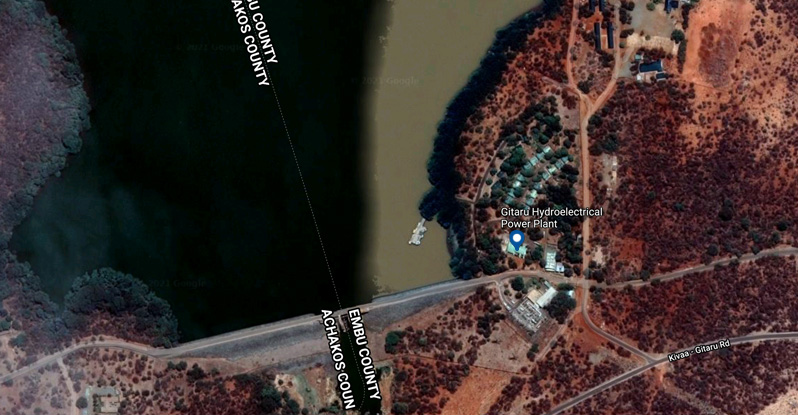

The Gitaru Hydroeletric Power Station is the biggest hydro power station in East Africa in terms of installed capacity. Located at the Gitaru Dam on the Tana River in Kenya, the dam crosses from Embu into Machakos County standing 30m tall with a reservoir capacity of 16 million cubic meter, producing 225MW. The dam was constructed in 1978 with the power station commissioned in 1999, operated by the Kenya Electricity Generating Company (KenGen).

The passage leading to the access tunnel at the Gitaru Power Station passes through complex cut terrain with the side slopes being almost vertical. There was a high risk of falling rock debris onto the track. Rockfall hazards can be a danger to any infrastructure or operations at the base of these slopes.

KenGen required a rockfall protection solution to minimize the risk of rockfalls onto the access road disrupting operations at the power station.

For moderately steep slopes the high-strength double-twist rockfall drapery mesh, galfan and polymer coated, was used. The mesh is secured to the rock slope at the top, base and intermediate anchors of the slope face keeping it as close as possible to the slope so that falling debris is contained behind the rockfall netting. It allows rock to fall to the base of the slope in a controlled manner. The high-strength mesh is an engineered combination of double twist steel wire mesh and high tensile wire ropes.

Not only is high tensile strength important, but stiffness for minimal deflection under load.

The double twist mesh offers several advantages compared to other mesh systems;

Maccaferri rockfall drapery systems are manufactured to the highest international standards and have been successfully used in various international projects. Geotextiles East Africa Ltd supplied the required 1,900sqm of Galfan Polimac coated mesh 80x100mm, Galfan Polimac lacing wire, 20mm dia. wire rope, termination grips and ordinary thimbles.